If you’ve heard of SureFire, there’s a distinct possibility you’ve heard of Chris Skahill. He has a tall, domineering stature, and a booming voice that carries, probably from his years as a firearms instructor, but his presence is strong enough to fill a room on his own. His quippy personality mixed with his straight demeanor is not surprising at all: having dealt in military contracting and customer relations, his breadth of knowledge on SureFire products, whether it be one of their 800 different flashlight SKUs, over 230 adapter options, or 12 different suppressors, is nothing short of impressive. His main role currently involves OEM customer service, weapon manufacturer services, as well as product integration for commercial and law enforcement and/or military integration. While he’s worn many hats as a SureFire employee, his job description can be whittled down to his official title currently as Key Accounts Manager. As a Key Account of SureFire’s, we hosted Chris Skahill for a one-on-one sale debrief, and an exclusive interview. Afterward, we set out to the range for a night shoot to test out some SureFire flashlights and suppressors, as well as take advantage of Chris’ many years as a firearm instructor. See the below Q&A between Silencer Shop and SureFire’s Chris Skahill.

Can you give us a little SureFire history lesson?

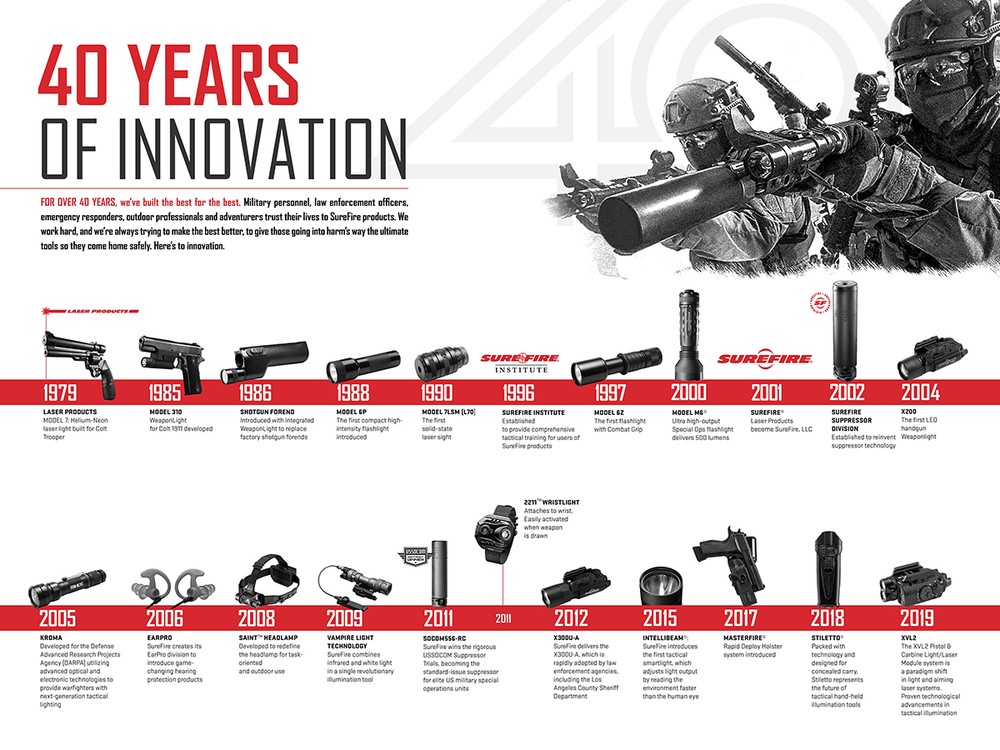

Yeah! Perfect. This year is our 40th Anniversary, and SureFire made this poster to show how we’ve evolved over the years. We’re still in Fountain Valley, California. Originally, the company started out making laser products in 1978. In the 70’s, lasers were like table lasers; there wasn’t anything miniaturized. So, our lasers were the first, not only miniaturized laser, but also weapon mountable laser. That was the evolution into Laser Products, which was the name of the company prior to it becoming SureFire, LLC. The official transition to the company being named SureFire, LLC was in 2001. In 2002, we formed a suppressor division. It’s no secret we make our silencers for military customers, so not only are the suppressors built for durability, they have also evolved directly due to the request of our military and consumer requests. Each item is optimized for a specific task or weapon, caliber type, or even cartridge.

You’ve touched on this a little bit already, but how and why did SureFire get into silencers?

SureFire got into silencers because of customer request. We look at the competitive landscape of what we made and what we liked and found where they fit within our customers’ needs. So, the only reason we jumped into these other categories, like suppressors, or other firearm accessories within the market is because we saw a hole and it fit within our customers’ needs.

A unique distinction for SureFire, LLC is that our suppressors are a division of SureFire. We are not a silencer company, but it is one of our divisions within the company that caters to commercial market, law enforcement market, and military market.

Specifically, for suppressors, we're certainly not inexpensive; totally get that. In some cases, we're not the quietest suppressor, and we're not the lightest suppressor. And those are all conscious choices that we made. The suppressor business model that we follow is a customer need or a desire for products, and the biggest request from our military customers is that there cannot be a dramatic shift of POA/POI from suppressed to unsuppressed. So, our testing criteria is that every one of our rifle and carbine suppressors is actually shot for validation at SureFire before going out the door.

Is testing every single silencer unique to SureFire?

Yes. There are different requirements for each project, but one of the things that we do differently than other manufacturers is that we test-fire all of our rifle/carbine suppressors before they leave SureFire, and we record every single target electronically for our archive in case we need to refer back to a specific suppressor at some point. Our Requirements Testing on SureFire Rifle, Carbine, and Machine Gun Suppressors is that the suppressors need to be able to shoot within 1MOA of a baseline group. The baseline group is established from that same weapon system unsuppressed. This validates and verifies the intended design criteria for limited POA/POI in each and every suppressor whether the suppressor is going to a government customer or the suppressor is going on the shelf at a local FFL. We make one suppressor version for all markets.

Prior to SureFire electronically recording every paper target, Barry Dueck, SureFire VP of Suppressors and Weapons, personally shot every suppressor with his protocol being that the group size had to be better suppressed than unsuppressed. The reason for having test fires on each suppressor is to ensure that it matches up to the POA/POI specifications. This adds time and effort from a production standpoint, but this is the only way that we can ensure without a doubt that EVERY suppressor stacks up.

Does SureFire source all American metals and materials in their silencers?

Yes, we do; all of our metals and materials are still sourced from the U.S. We scan all metals coming through for the QC [Quality Control] process to make sure that it's within our standards range. That way we're not having a bad batch, and then making a product that could have a potential failure point.

For years, you guys were dedicated to the rifle silencer. What was the impetus that moved you guys into the Ryder line of pistol and rimfire silencers?

Really, us moving into pistol and rimfire silencers was commercial request. For the longest time, and really our primary focus has always been military customers and law enforcement. Then it finally got to the point where we were seeing a hole in the commercial market for the subcaliber direct thread style of suppressor. So, we came up with it. It started off initially as the 22A model, which was an aluminum tube, aluminum baffle stack, with a red anodized big nosed baffle design. Those were for 22 long rifles only. But we had enough customers request other items. So, we ended up coming out with a 22S, which is the current 22 full size suppressor today. Then the Ryder 9 came out. We've had some adoption of those suppressors with our military customers, but our larger volume is going to be on the commercial side. We saw it as fleshing out the suppressor line. And that was our logic getting into manufacturing these silencers - is having an option on the quality build type of SureFire for some of these other subcaliber weapon systems.

Along those same lines, what was the reasoning for branching out from the 100% Inconel cans into other metals, like stainless steel and titanium?

When we got into Titanium cans, it was kind of just strictly from a weight saving standpoint, but more so for the precision. As for our long range suppressors, our first Titanium was going to be the 338-Ti, then the 300-Ti and the 260-Ti, which is for our 6.5 guns. These were strictly from a weight savings standpoint. Titanium suppressors can be used on a precision gun, bolt gun, or semi-auto for that precision use. But we certainly do not recommend them for mag dumps or any type of assaulter-type use because the Titanium suppressors will not hold that same rate of fire. You’d start seeing erosion and issues as time goes on. Traditionally, all of our SOCOM-2 Series are all going to be an Inco [Inconel] can of different grade and variant, and with a couple different proprietary design queues and manufacturing styles. But we also realized that we can use different types of metals and still be efficient and still have full auto ratings depending on caliber types.

What does SOCOM mean to the consumer? What're the standards?

The standard for the SOCOM line is truly customer specified. US SOCOM (Special Operations Command) had very specific requirements for a suppressor, and SureFire developed an entire line around these criteria. The first and foremost requirement was for a minimal POA/POI. We test and shoot each suppressor as a final quality control, and these have to shoot within 1MOA otherwise the suppressor doesn’t get sold. Next, we test flash suppression. While flash is not a primary concern of most of our commercial customers, it certainly is with our military customers. We build our flash hiders and WARCOMP’s to this same standard to limit the ability of being identified. Blowback is always a consideration when shooting suppressed, however, it cannot be a detracting factor. Most military weapon systems do not have an option to adjust the gas setting, so SOCOM suppressors are designed to have a lower gas blowback compared to most commercial silencers which allows for better operability of the weapon system and the shooter. Durability is a key factor as the suppressor has to last the rigors of hard use because there are no time-outs in a fight. Sound is certainly a consideration but was not a chief requirement of the customer as long as it was tolerable to the shooter’s ear, and we are well within that range. Our patented Fast-Attach system allows for one-handed attachment and removal. Simplicity is the key for having a good lockup attachment. Longevity would be the last piece to the puzzle. There is no determined lifespan for SOCOM suppressors. We have several customers now who have shot their suppressors over 100,000 rounds while still maintaining sound and flash reduction.

Why go with a 260 series?

Going with a 260 series was military customer request. Originally when that cartridge was becoming prevalent, it was between 260 and 6.5 [Creedmoor]. It was looking like the 260 was going to be 260, so that’s why we named our suppressor the 260. And then we bring it to market, and everybody is like, “6.5!” It’s the same thing. I know it’s a different cartridge, and it’s different chamber pressures, projectile options, and ballistic coefficients, however, it’s going to use the same suppressor for us.

So, does it make sense to go with a dedicated 6.5 suppressor?

For optimum performance, yes. But, leading up to that 260-suppressor coming out, our recommendation was going 7.62RC2 with a 7.62 5/8x24 SOCOM adapter. The 260 option was initially based off of a military requirement. We brought our suppressor options and adapters to market during the growing popularity of 6.5 Creedmoor. The .260 Remington has a slightly lighter muzzle velocity compared to 6.5 Creedmoor, but there is no issue with using either on our suppressor selections. For all intents and purposes, SOCOM260-Ti or SOCOM260-RC2 can be used for 6.5 Creedmoor too. The only difference is the Titanium (Ti) option would be recommended for precision use while the RC2 (Inconel) is full-auto rated, and can handle a significantly higher shot schedule.

Why come out with the SOCOM 300Ti? What purpose did it serve?

The SOCOM 300Ti is a suppressor that is best suited on a precision rifle. Weight is always a consideration when adding a suppressor for precision shooting, and with a suppressor coming in at only 11oz this is a considerable weight savings. It is certainly capable on both bolt and semi-auto guns, but the weight savings does have a tradeoff with durability. As long as this suppressor is being shot within a precision role there is not an issue with shot frequency.

“And that's really been the main criteria for SureFire suppressors since the beginning. It can't be, ‘Oh it's great but...’ It's got to be an accessory that doesn't have any negative effect to the reliability of the host firearm.”

How is it that SureFire has less blow back than most commercial suppressors?

What we have found, in some of our own testing, to exclude maybe a couple of the other manufacturers of suppressors, is that we have about a one-third less back pressure. And the biggest reason that we have this built into the design is that the suppressor is vented and the gas is redirected within the baffle stack. For the flow of the gas, the thing that we don't have the luxury of, specifically for the military customers, is having any kind of adjustable system. So, the firearm has to operate, run, and fire, as it does unsuppressed. And that's really been the main criteria for SureFire suppressors since the beginning. It can't be, "Oh it's great but..." It's got to be an accessory that doesn't have any negative effect to the reliability of the host platform.

What about your 2019 lineup? Let’s talk about what’s come out.

2019 brings more Titanium suppressors to the line-up. We have had the SOCOM338Ti for a number of years now and having that weight savings in specific caliber ranges has been the big ticket this year. Now, we have the SOCOM300-Ti which is essentially the SOCOM300-SPS, but in a Titanium option, as well as the SOCOM260Ti for 260 or 6.5 variants. Also, the SOCOM260-RC2 gives the shooter the caliber specificity of 260, but an in Inconel option for a higher volume of shooting compared to the Ti version. We also have the SF-OBC-5.56, and the SureFire Optimized Bolt Carrier Group, specifically for direct impingement guns. So, those are all out now; they’re shipping and available.

Is there anything you can tell us coming up in the next few months?

The PLR-B Stiletto Pro Handheld, XVL2-IRC Weapon Light, and RYDER 9Ti-2 Suppressor are near term... Otherwise, stay tuned.

Can you tell me a little more detail about the Ryder 9 Ti-2?

The RYDER 9 Ti-2 will have a larger interface area where the piston contacts the back section along a new internal coating on these parts to reduce carbon fouling buildup. Also, there will be a few new design queues to be added to the update. They’ll just be simple revisions for a better user experience.

What is TSR and what does SureFire do in "signature reduction" that other manufacturers don't even consider?

TSR is Total Signature Reduction, and it specifically refers to sound, flash, and gas/over pressure reduction. We consider this balance to be the true requirements for a suppressor. The intent of SureFire, since the beginning of the Suppressor Division being stood-up, has always been to have a suppressor option designed for duty-use both in the Law Enforcement and Military space. Our government customer requirements have not had sound as a leading factor, but certainly something to be included. The primary intent has always been to have a signature reduction for flash, over pressure, and sound as a combination. TSR is truly a full package.

Talk to us about the differences in RC, MG, and SB SOCOM cans.

At SureFire, we make optimized suppressors for different rifle and carbine considerations even within the same caliber or weapon type. The RC moniker stands for Rifle/Carbine which in the case of the SOCOM556-RC2 option, it is best suited for 10.3” barrels or longer. The SOCOM556-MINI2 is optimized for 14.5” barrels or longer while still maintaining the same flash and sound suppression seen with the RC2 option on a shorter barrel. The SB2 ( Short-Barrel) would be for anything less than 10” or for a short piston operating system (ex. HK G36) to allow for more pressure to exit through the suppressor instead of potentially causing stoppages, increasing wear on the weapon systems, and further increasing gas blowback. While all SOCOM Series Suppressors are full-auto rated, there is an MG (machine gun) option for belt-fed systems or if the intent is for a suppressor to be shot on full-auto primarily. In the case of attaching the SOCOM556-MG (Machine Gun) a standard SOCOM 5.56 Adapter is used while the SOCOM762-MG (Machine Gun) requires a specific adapter (ex. SF3P-762MG-M240) which is larger to increase bearing surface interface for added strength. For instance any SOCOM Series 5.56 Suppressor, either Gen1 or 2, from MINI through MG can be attached with either a Flash Hider (SF3P), Muzzle Brake (SFMB), WARCOMP, Closed Tine Neutral (CTN) or Close Tine (SFCT), but the SOCOM762-MG suppressor will only attached to 762-MG Suppressor Adapters.

Can you talk about the lock up for the Ryder 9- MP-5? What were the requirements when designing it and what it needed to do?

“Customer request has been the driving factor in almost all of our products.”

Yes, this is an excellent example of fulfilling a customer requirement. Commercially, there has been a call for a tri-lug adapter for the RYDER 9-Ti. We know that a screw-in back section being hand installed will not last to SMG fire. As with most of our products, a government customer was coming to us with a need. The intent in spec’ing the lockup for the RYDER was for it to be an extension of the weapon system rather than an accessory. A fair amount of feedback from customers was that their existing QD system suppressors, when contacted, would shift impact considerably, as well as, in some case become disconnected from the weapon system. The RYDER 9-MP5 has a welded back section, modified locking ring to engage a tri-lug barrel, and a steel tube. Our Titanium tube on the RYDER 9-Ti is still full-auto rated, however, a Ti tube might not hold up to doorways, bulkheads, windows, barriers, etc. for law enforcement and military, hence, the steel tube in the RYDER 9 MP5.. The suppressor still disassembles just like the rest of the series. This allows for the ability to clean from the front. This has not been a big seller for us, but customer request has been the driving factor in almost all of our products.

Why should customers buy SureFire?

“A well-balanced suppressor that has ease of attachment and does not have a known lifespan translates to the commercial market as well. Purchasing a SureFire suppressor is an investment in a lifetime suppressor.”

SureFire’s commitment in product is directly done for customer satisfaction. We build the best product available for the task that it is intended for… hard use. It’s no secret that our primary customer base is law enforcement and military customers, and our suppressors by large are designed for duty use. A well-balanced suppressor that has ease of attachment and does not have a known lifespan translates to the commercial market as well. Purchasing a SureFire suppressor is an investment in a lifetime suppressor.

What is the perfect silencer to you? What's that mean? Modular? Monocore? Stainless?

“Durability is the name of the game. This suppressor will last the rest of my life.”

In my experience, modular suppressors are trying to do everything for everyone and does not do any one thing well. Monocore might be decent for a direct thread rimfire suppressor but are a pain to clean. Stainless is a broad term, and at its simplest term is cheap and easy to manufacture but does not do anything for the end user for longevity. If we are talking stellite, is cuts easier for manufacturing, but still not the pinnacle. The perfect suppressor for me would be a 5.56 option. Not to make this sound like a sales pitch, but I would have to say SOCOM556-RC2. I shoot 5.56 more than anything else these days and having a suppressor which is optimized for this round and barrels 10.5” or longer. Shooting a select-fire MK18 is always great which calls for an Inconel option. I personally own a SureFire FA556-212 which is the previous generation to the SOCOM Series. It started as my demo suppressor which I have over 40k rounds through. Durability is the name of the game. This suppressor will last the rest of my life.

If you could only own one gun, silencer, and flashlight, what would they be and why?

Sig Rattler, SOCOM300-SPS, X300U. This is my favorite set-up right now. It covers all the needs. I can shoot sub or super-sonic, run suppressed, it fires in the folded position, and is nice and compact. You just have to use a tapered space to be able to get the WARCOMP-762-5/8-24 Adapter installed. I run the X300U-B inverted on the 12 o’clock position for ease of shooting ambidextrous. I don’t know that I’d need more than 1,000 Lumens of viz light on this configuration. If I was going for historical cool, it would have to be High Standard HSM .22 pistol with integral suppressors. I’m intrigued with the history of suppression starting with Hiram Percy Maxim, the inventor of the silencer, at the turn of the 20th-century, but still the Office of Strategic Service suppressed pistol is awesome for what it was at that time. I had a chance to have seen a couple of these at different museums and collections. For a light in that timeline… maybe a zippo? Ha.

Dedicated to their military and civilian customers, SureFire directly attributes their ingenuity and originality to building out their customers’ requests. SureFire has gotten down to the meat and bones of perfecting and tweaking products in an effort to develop their inventory line with task-oriented focus. If you’re looking for durability, and the ability to truly test your silencer’s limits, SureFire is definitely a company to consider. With Chris Skahill sharing his wealth of knowledge, we’re definitely feeling SureFire rich, and we hope you are too! Is there anything we didn’t cover that you would have asked? Let us know in the comments below.