A suppressor, also known as a silencer, attaches to a firearm's barrel to reduce the noise produced when firing. When a gun is fired, high-pressure gases propel the bullet through the barrel and exit rapidly, creating a loud sound. A suppressor contains a series of baffles and expansion chambers that trap and slow these gases, allowing them to cool before releasing them into the atmosphere. This process decreases the sound of the gunshot by many decibels, making shooting safer for hearing and reducing noise pollution.

Table of Contents

What is a Gun Suppressor?

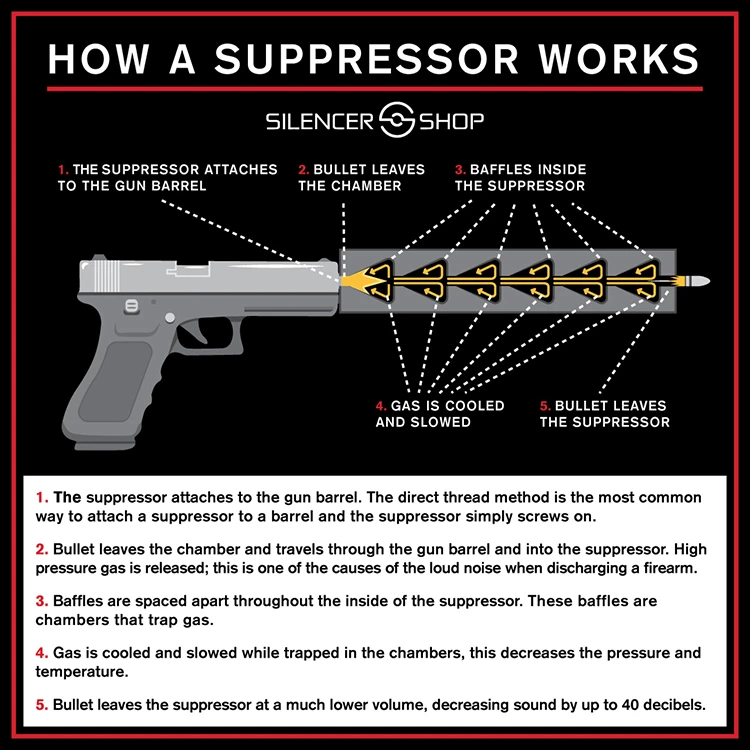

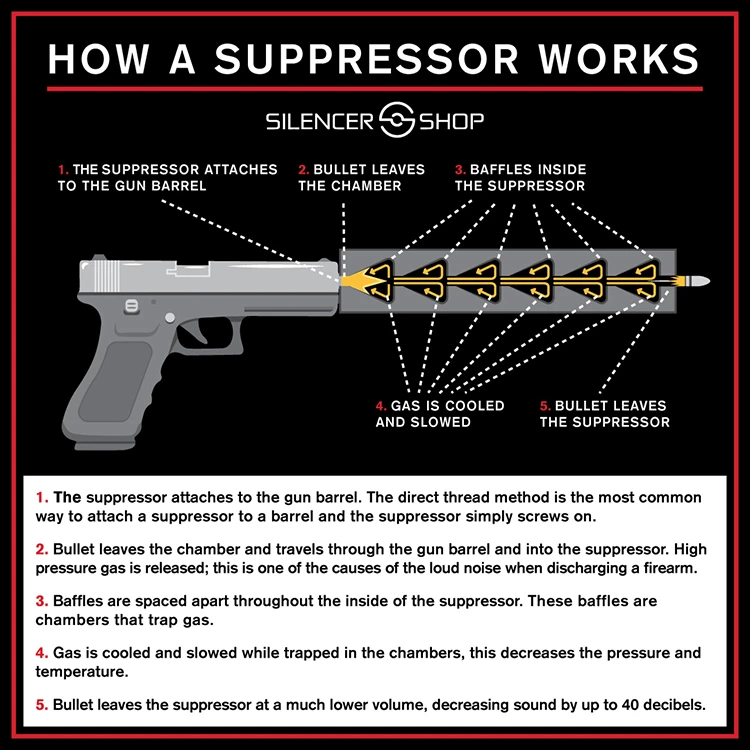

A firearm suppressor is a device that attaches to the gun barrel to reduce the noise from the gunshot. When a gun is fired, the bullet leaves the chamber and travels through the barrel; it instantly uncorks thousands of pounds per square inch (PSI) of gas pressure behind it. For example, when an AR-15 is fired it releases over 8,000 PSI at the muzzle. The bulk of an unsuppressed gunshot’s noise comes from the extremely high-pressure gas rapidly decompressing into the atmosphere.

Adding to the intensity: muzzle gases are typically traveling at supersonic speeds and are scalding hot, and both of these factors contribute to the extremely high level of sound. While there are other factors that contribute to the volume of a gunshot, the release of hot, high-pressure, and supersonic gas is by far the largest contributor to the sound of a firearm and this will be dramatically reduced when you use a suppressor.

What Does a Suppressor Do?

How a suppressor works is by dramatically reducing a gunshot noise by slowing the decompression of hot, high-pressure gasses. A firearm suppressor creates a controlled environment in which these gases expand and cool before they make contact with ambient air. Imagine untying a balloon instead of popping it, or slowly removing the champagne cork just enough for gas to vent in a slow and steady fashion: you would hear a hiss instead of a pop.

Do Silencers Work?

Yes, silencers are an effective way to provide hearing protection, with most models providing as much or more sound reduction in decibels (dB) as the most effective over- or in-ear sound protection. Instead of blocking out the sound at your ear, you’re blocking the sound at the muzzle. Silencers give the gas of the gunshot ample space to expand, while using various means to slow down, trap, and redirect the gasses inside so they’ve dropped as much pressure and temperature as possible when the gases exit the muzzle. Attaching a silencer to your firearm is a substantial improvement when you’re hunting, target shooting, or otherwise engaging with your firearm. By attaching a suppressor to your firearm, you’ll have the hearing safety benefits of over-ear hearing protection, without sensory deprivation or the added bulk/weight on your head.

What is Inside of a Suppressor?

Inside a suppressor, there are a series of baffles, and chambers that trap and slow the high-pressure gas that is created when the firearm is discharged. These baffles, which are flat or cone-shaped, are spaced apart to create expansion chambers inside of the suppressor body. The suppressor’s baffles can be machined in any of three main ways: 1) out of a single piece of metal (monocore), 2) machined individually then welded together, or 3) machined individually and stacked on top of each other inside of a tube. Some silencers are additively manufactured (3 printed) via a direct metal laser sintering process (DMLS). The materials used inside a suppressor, especially the first baffle (also known as the “blast” baffle), must be capable of handling high heat and pressure, as well as some high-speed debris that blasts out of the barrel.

What Metal is Best for Suppressors?

Suppressor materials vary from 7075 aluminum to titanium to 17-4 stainless steel to name brand superalloys like Inconel and Stellite. When engineering a silencer, the manufacturer will evaluate weight, cost, machinability, and durability so it can be used for generations. All suppressors are designed with the same goal: to slow the speed, slow the expansion, and cool the gunshot gasses before they hit the ambient air.

Sometimes, some of this gas is redirected toward the shooter's face making it unpleasant to shoot for extended periods of time. When this occurs, the redirection of gas can be referred to as backpressure: gas pressure that’s pushed back up the bore of the barrel toward the firearm. As an alternative to baffles, some silencers use internal channels and passages to block gas expansion and delay the gas by giving it a farther distance to travel. These designs endeavor to reduce backpressure which is a side effect of most baffle-style suppressors. Left-handed shooters will find this especially beneficial, as there will be less backpressure from the ejection port when shooting a rifle. Examples of this style of suppressor are HUXWRX (formerly OSS) Suppressors’ rifle silencers and SIG SAUER’s SLX and SLH line.

How A Silencer is Made

The majority of silencers are made using either a mill or a lathe. A silencer’s baffles, monocores, mounts, front caps, and other features are machined from pieces of raw aluminum, stainless steel, titanium, or other material.

Want an in-depth look at the silencer manufacturing process? Check out this Behind the Scenes mini-documentary to see how SureFire suppressors are made.

What Are Most Suppressors Made of?

Most suppressors are machined from bar stock with some components welded or screwed together. In other cases, they are simply stacked on top of each other inside of a tube with a mount on one end and a cap on the other. “Hybrids” are when a combination of these two methods are used when constructing the suppressor.

Direct Metal Laser Sintering or DMLS is a manufacturing technique that is rapidly gaining popularity. It’s an additive manufacturing process – 3D printed suppressors – that works with metal by laser fusing thousands of layers of powdered metal together one layer at a time. The DMLS process is capable of creating complex internal structures that cannot be machined. Many of the “flow-through” silencers with intricate internal channels and passages are made via DMLS. DMLS-manufacturers include SIG SAUER, Daniel Defense, CGS, HUXWRX (formerly OSS Suppressors), and Radical Firearms.

Precise manufacturing of silencers is crucial because all silencers are designed to strip gas away from the bullet as it passes through the bore. This typically involves the bullet flying through a tunnel of holes cut through a series of baffles. These baffles are spaced throughout the inside of the suppressor. These baffles are chambers that trap gas. From the mount to the front cap, each section of threads, each machined face, and every borehole in all baffles must be precisely aligned with one another and with the bore of the host firearm’s barrel.

What’s the Best Finish for a Suppressor?

Silencer finishes must be capable of withstanding intense heat: common finishes include anodizing, nitriding, and high-temperature Cerakote.

Photo Credit: @ruggedsuppressors

Conclusion

All silencers work by controlling and slowing gas expelled from the barrel of a firearm. What are the benefits of using a silencer? By preventing the rapid expansion of thousands of pounds per square inch of gas pressure, the bullet leaves the suppressor at a much lower volume, decreasing sound by up to 40 decibels. While materials and internal designs vary, this basic function is common to every suppressor.

The easiest way to get a suppressor is with Silencer Shop. What ATF form is needed for a suppressor? With an eForm 4 Powered By Silencer Shop, you can expect to get your suppressor in 90 days, per the ATF, with some customers receiving their Form 4 suppressor in as little as 7 days.

Silencer Shop is the largest NFA distributor in the United States and with over 25,000 reviews on Trust Pilot and an average ranking of 4.9 out 5 stars, you can experience silencer ownership, simplified.